نظرسنجی

نظرسنجی

پیوندها

دستهها

ابر برجسب

رایگان نمونه سوال مهندسی پلیمر پلیمر دانشگاه پاسخنامه خبر دانشگاهی گزارشکار دانشجو مهندسی نمونه الیاف دانلود پیام نوربرگهها

- علم رنگ

- پلی کربنات

- آشنایی با مهندسی پلیمر

- پلیمرهای سیلیکون

- روغنهای سیلیکون

- پخت دوجزئی وینیل

- تبلور

- نمونه سوال تکنولوژی مواد واسطه

- سخت شدن رزین های اوره- فرمالدئید

- زینک فسفات

- آشنایی با مهندسی پلیمر بخش 2

- انجمن مهندسی پلیمر دانشگاه پیام نور مشهد

- رزین های اپوکسی

- رزین اوره فرمالدئید

- رزین اوره فرمالدئید (فارسی)

- فرمالدئید

- نمونه سوال ترمودینامیک

- جزوه انتقال حرارت

- حل المسائل انتقال حرارت

- نمونه سوال ریاضی 1

- ترجمه مقالات و متون تخصصی و عمومی

- ژل ریسی

- الیاف و انواع آن

- آشنایی با روش های ریسندگی و تولید الیاف ساخت بشر

- رنگ های کمپلکس فلزی

- ریسندگی الیاف نوری

- کاربرد رنگ های ازو کمپلکس کروم

- عرضه پوشش جدید ضدخوردگی با قابلیت خودترمیمشوندگی

- جزوه سینیتیک پلیمرزاسیون (سنتز)

- Acid dye

- رنگ های اسیدی (انگلیسی)

- رنگ های اسیدی قسمت2 (انگلیسی)

- الیاف بی بافت

- ریسندگی الیاف نوری:

- انواع رنگ های اسیدی (فارسی)

- انواع رنگ های نساجی

- کتب تخصصی

جدیدترین یادداشتها

همه- [ بدون عنوان ]

- مژده مژده

- لینک کانال تلگرامی ما

- تولید نانوالیاف پلیمری در ترمیم بافتهای آسیبدیده بدن توسط محققان ایرانی

- نمونه سوال کنترل فرآیند

- نمونه سوال تربیت بدنی(ورزش1)

- گزارشکار کارگاه تکنولوژی و تولید پینت

- نمونه سوال دانش خانواده

- گزارشکار آزمایشگاه شیمی فیزیک

- گزارشکار آزمایشگاه مواد واسطه و رنگزا

نویسندگان

بایگانی

- مرداد 1395 1

- اردیبهشت 1395 1

- بهمن 1394 3

- دی 1394 1

- آبان 1394 1

- مهر 1394 3

- مرداد 1394 4

- خرداد 1394 5

- اردیبهشت 1394 3

- فروردین 1394 3

- اسفند 1393 1

- بهمن 1393 2

- دی 1393 13

- آذر 1393 13

- آبان 1393 2

- مهر 1393 11

- شهریور 1393 6

- مرداد 1393 10

- تیر 1393 16

- خرداد 1393 22

- اردیبهشت 1393 4

- فروردین 1393 13

- اسفند 1392 29

- آذر 1392 4

- آبان 1392 3

تقویم

مرداد 1395| ش | ی | د | س | چ | پ | ج |

| 1 | ||||||

| 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| 16 | 17 | 18 | 19 | 20 | 21 | 22 |

| 23 | 24 | 25 | 26 | 27 | 28 | 29 |

| 30 | 31 |

جستجو

ژل ریسی 2 (انگلیسی)

It

is also known as dry-wet spinning because the filaments first pass through air

and then are cooled further in a liquid bath. Gel spinning is used to make very

strong and other fibers having special characteristics. The polymer here is

partially liquid or in a "gel" state, which keeps the polymer chains

somewhat bound together at various points in liquid crystal form.

This bond further results into strong inter-chain forces in the fiber

increasing its tensile strength. The polymer chains within the fibers also have

a large degree of orientation, which increases its strength. The filaments come

out with an unusual high degree of orientation relative to each other, further

enhancing strength. The high strength polyethylene

fiber and aramid fibers are manufactured

through this process.

Whatever spinning process is applied, the fibers are finally drawn to increase strength and orientation. This may be done while the polymer is still in the process of solidifying or after it has completely cooled down. Drawing pulls the molecular chains together and orients them along the fiber axis, resulting in a considerably stronger yarn.

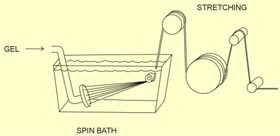

Gel spinning

Gel spinning is a special process used to obtain high strength or other special fiber properties. The polymer is not in a true liquid state during extrusion. Not completely separated, as they would be in a true solution, the polymer chains are bound together at various points in liquid crystal form. This produces strong inter-chain forces in the resulting filaments that can significantly increase the tensile strength of the fibers. In addition, the liquid crystals are aligned along the fiber axis by the shear forces during extrusion. The filaments emerge with an unusually high degree of orientation relative to each other, further enhancing strength. The process can also be described as dry-wet spinning, since the filaments first pass through air and then are cooled further in a liquid bath. Some high-strength polyethylene and aramid fibers are produced by gel spinning.

WET AND GEL SPINNING TECHNOLOGY

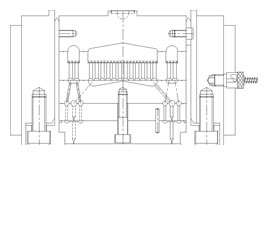

For those projects where melt spinning solutions cannot succeed, FET designs and manufactures Laboratory and Pilot Wet and Gel Spinning Systems. This process is used for polymers that need to be dissolved in a solvent to be spun.

In the case of wet spinning, the spinneret is submerged in a chemical bath that causes the fibre to precipitate, and then solidify, as it emerges. Gel spinning is sometimes described as dry-wet spinning, since the filaments first pass through air and then are cooled further in a liquid bath.

Solvent spinning is used to obtain high strength or other special properties in the fibres. The polymer is in a "gel" state, which keeps the polymer chains somewhat bound together. These bonds produce strong inter-chain forces in the fibre, which increase its tensile strength. The polymer chains within the fibres also have a large degree of orientation, which increases strength. Some high strength polyethylene fibres are produced via this process.

Wet and gel spinning applications:

Based on a modular concept, FET Wet and Gel Spinning systems are used for a variety of solvent and polymer combinations and are being operated worldwide.

Wet and Gel spinning as a tool for engineering new functional textile materials

Allows maximisation of polymer and hence fibre properties Available for multifilament, monofilament and fibre in both laboratory and pilot scale Bio-medical applications

optimisation of process conditions for transfer to production systems

All FET Wet and Gel spinning systems are tailor made and take into account required throughput polymer/solvent combination and downstream process conditions.